From Tree to Table

It Happens Early Spring…

In the early Spring as the outside temperatures begin to warm something wonderful begins to happen in the Maple Bush!

The trees begin to awaken from winter’s rest, and like anything that comes to life after a long rest the trees begin to look for food, knowing that to survive and grow they must be fed. The root system buried within the ground begins to draw moisture and nutrition sending it upward through the trunk to the branches. As this sap passes through the sweet maple wood we do something that has been done for centuries.

We drill a hole! about one and a half centimetres in depth, into the white wood of the maple tree. If all the conditions are right a clear sweet liquid will begin to drip from the freshly drilled hole.

To capture this clear liquid we will insert a plastic device called a spile into the hole. Next we fasten a plastic tube to the spile. The tube is part of a large gathering network of above ground and underground pipeline that will carry the sap to storage tanks.

Entering the Evaporator for boiling…

When we have enough sap to begin making Maple Syrup we will push the sap through a series of filters known as Reverse Osmosis. These filters will remove water from the sap. By removing water our boiling time will be reduced by more than 60 percent. This filtering will not change the taste or texture of the finished maple syrup product and has a couple of benefits. By reducing boiling time we are able to keep our costs of production down. Because we are able to use less energy producing a litre of syrup the enviromental footprint per litre is also reduced.

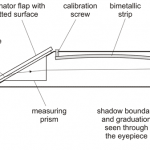

Once the sap has passed through the Reverse Osmosis filters it is ready to enter the Evaporator for boiling. By it’s very name, Evaporator, we know that the sap must be boiled to continue removing water by evaporation. As the water evaporates the remaining liquid becomes thicker and thicker until it reaches that perfect blend of 66% sweetness (the density of syrup is measured in Degrees Brix with the finished product registering 66 Brix on the scale). To test the syrup’s density during boiling we use a Refractometer. A drop of syrup is placed on a window of the refractometer allowing light to pass through the syrup causing a refraction measuring the density by using an internal scale.

Degrees Brix (symbol °Bx) is the content of an aqueous solution. One degree Brix is 1 gram of sucrose in 100 grams of solution and represents the strength of the solution as (% w/w)

The syrup product develops…

Once the maple syrup has reached the correct density of 66 Brix the boiling is complete. The syrup will then be filtered through a series of paper filters in a Filter Press before Canning or Barreling.

Filtering the sap removes a small amount of mineral left at the end of boiling. The syrup industry refers to this mineral product as “sugar sand”. Sugar sand is not harmful but could create a cloudiness or sediment in the syrup, therefore it is removed to produce a clear product.

The canned maple syrup will be sold within our gift shop as well as a few locations in the area. The barreled syrup will be sold in bulk form by the pound and is often exported.

Take a trip to the Sugar Bush…

Gilbertson’s maple products works hard to bring you, the customer, a quality product and invites your comments on your trip to the sugar bush.

- Lines in the Sugar Bush

- Reverse Osmosis

- Refractometer

- Filter Press